COLUMBUS BODY WORKS

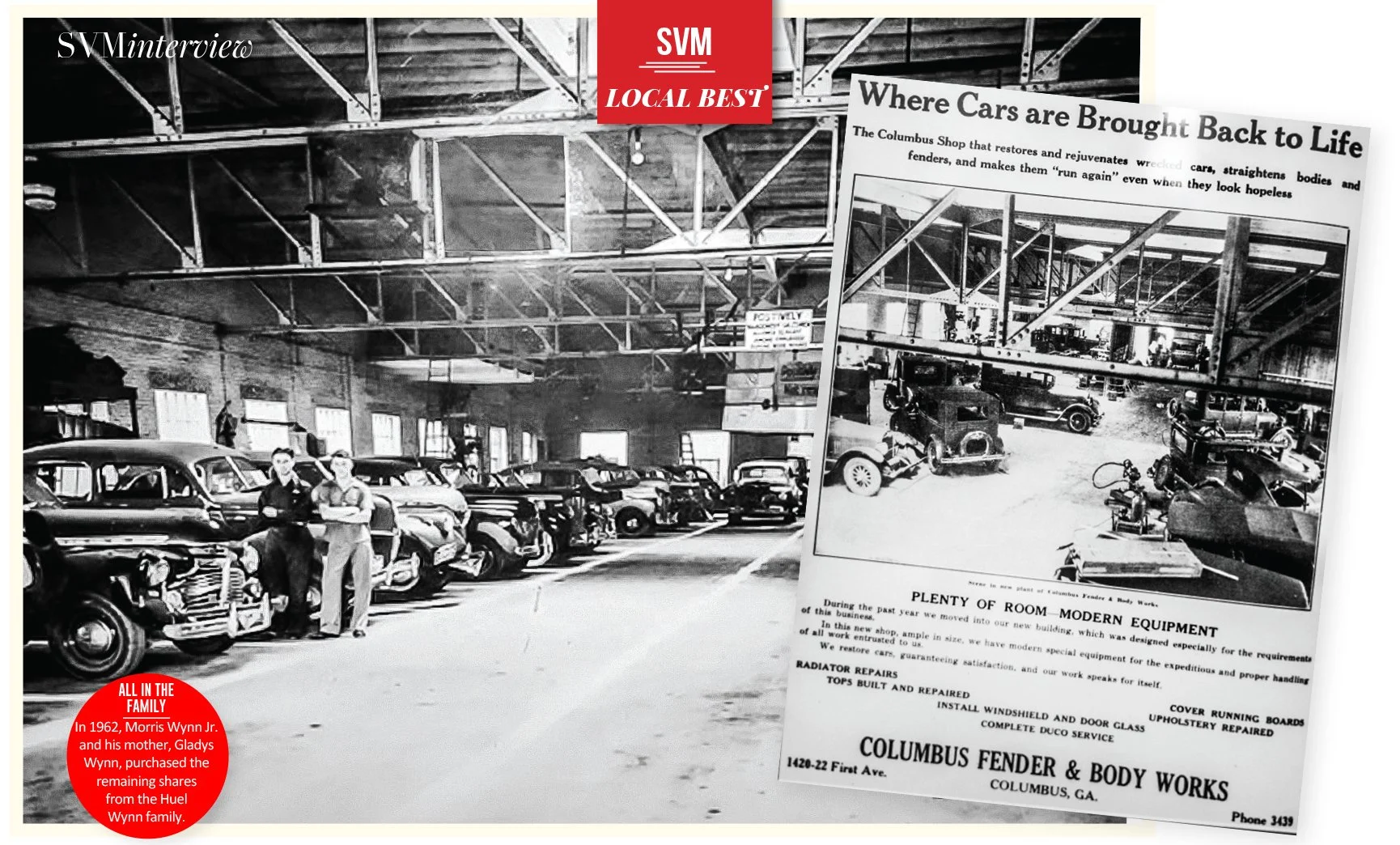

Columbus Body Works was founded in 1918 by Huel and Morris Wynn. The first location was on Broad Street in downtown Columbus Georgia. In 1925, CBW moved into a custom-built, state of the art facility located at 1420 1st Avenue. The modern facility had the first “Bear” frame and alignment system which makes CBW one of he oldest complete body shops in the south. Much has changed over the decades (including the name), but one thing remains constant — Columbus Body Works dedication to quality and customer satisfaction.

Philip Wynn grandparents opened Columbus Body Works in Columbus in 1918,. Back then, it was called Columbus Fender & Body Works. Philip has been running CBW since 1991. Philip spoke to SVM about the beginnings of the company, their secret to success, and what people should look for when selecting a body shop.

Tell us about the history of Columbus Body Works. Columbus Body Works was founded in 1918 by my grandfather’s brother- Huel- and a close friend, T.J. Flanagan. The first shop was located on Front Ave. In 1923 my grandfather Morris Wynn took over Mr. Flanagan’s role. The two remaining Wynn brothers built a “state of the art” shop in 1925 on 1st Ave., where the Downtown Elementary Magnet Academy is now located. We were the first shop to purchase a frame repair machine for the new facility. That purchase made us the first full service collision center in the South. After years of hard work, my father and grandmother took full control of the business. In 1988, we moved from the 1st Ave. location to our current location on Veterans Parkway just a few blocks north. At the time, we were the only collision center in the United States to have air conditioning throughout the entire facility. Many shop owners from around the U.S. would come to see our modern facility. In 1992, I joined the family business. We have added a second location on the north end of Veterans Parkway (Columbus Body Works Northlake) and other auto supporting businesses including Columbus Auto Glass and Rhino Linings of Columbus. We have also started a consulting business, Aftermarket Automotive Solutions, to help young shop owners thrive in the field.

For a family-run business, it’s quite an achievement to not only survive, but to thrive as long as Columbus Body Works has. What is the company’s secret to success? Our customer service and attention to detail. We want all of our customers to be happy. We are now seeing 4th generation customers.

What’s the most unusual or interesting job Columbus Body Works has handled? In the late 60’s, my father received a call from a large Los Angeles bank. The lady on the phone told him the bank president would like to speak with him, so he took the call. The bank represented Black Jack Productions. My father didn’t have a clue who Black Jack Productions was. He was then told the production company was a John Wayne Movie Company. His response was YES we will be glad to help. John Wayne Movie Company came to town to produce The Green Berets. The movie involved a Chrysler automobile that would get wrecked during different scenes of the movie. They would bring the car to us in the evening and we would go to Atlanta right away to pick up the needed parts. The shop would work all night for the car to be ready by the next scene.

In my early career, I can remember an executive from Kinnett Dairies bringing in about 10 different empty milk jugs. They wanted to have samples of different shades of white and cream for their new milk jugs’ color. It was neat to see them pick from such close colors. A few years later, Char-Broil had just finished a new grill top for a major spring outdoor convention. The final product was ready just weeks before the show. When the tops were stamped they had slight waves in the metal. They didn’t have enough time to correct the issue before the show, so we used Bondo to finish them off evenly and then painted them. They were ready in time for the convention. Char-Broil corrected the tops before they went onto market.

How has body work repair evolved over the years? The first major change I’ve seen in body repair is the change from metal to aluminum. It started as bolt-on parts and now some cars are completely aluminum. This change has been very expensive to the industry and only a few shops have all the correct equipment to repair as needed. The second major change is technology. Navigation was first, then self-driving cars started to show up. We are learning fast, as we are the only Mercedes-Benz and Tesla Certified shops within 100 miles of Columbus.

Give us a little insight into how evolving technology is impacting the Auto Repair industry? ADAS, or Advanced Driver Assist Systems, are the computers that tell you there is a car coming up from behind, or a car in the lane next to you. It is neat to watch how much a car can do on its own.

From your years of experience, what are the top things people should look for when selecting a body shop? Reputation and years of service. Value over price. Clean and neat outside appearance. If the outside looks unorganized, then what does the inside look like? We welcome our customers to take a shop tour if they are in doubt.

In the years you have been in the industry cars have changed so much, what is your favorite thing cars are equipped with now that they were not when you started? Luxury interiors.

Auto insurance policies can be complicated, and sometimes offer some surprises to customers when the time comes to use it. Do you have any general advice when it comes to auto insurance? Pick a company that doesn’t talk about being the cheapest, you will see what little 15% or so has saved you when you need them. Most good insurance companies have good reputations. Be careful of some of the large discount carriers. Most local agents take very good care of their customers. If the actual underwriting company is massive, you might be just a number. Shop value not price.